A home-made record player

Somehow I thought building a custom record player from scratch would be a good idea. It ended up taking 7 years in the building and many many iterations. Here is a photographic record of the process.

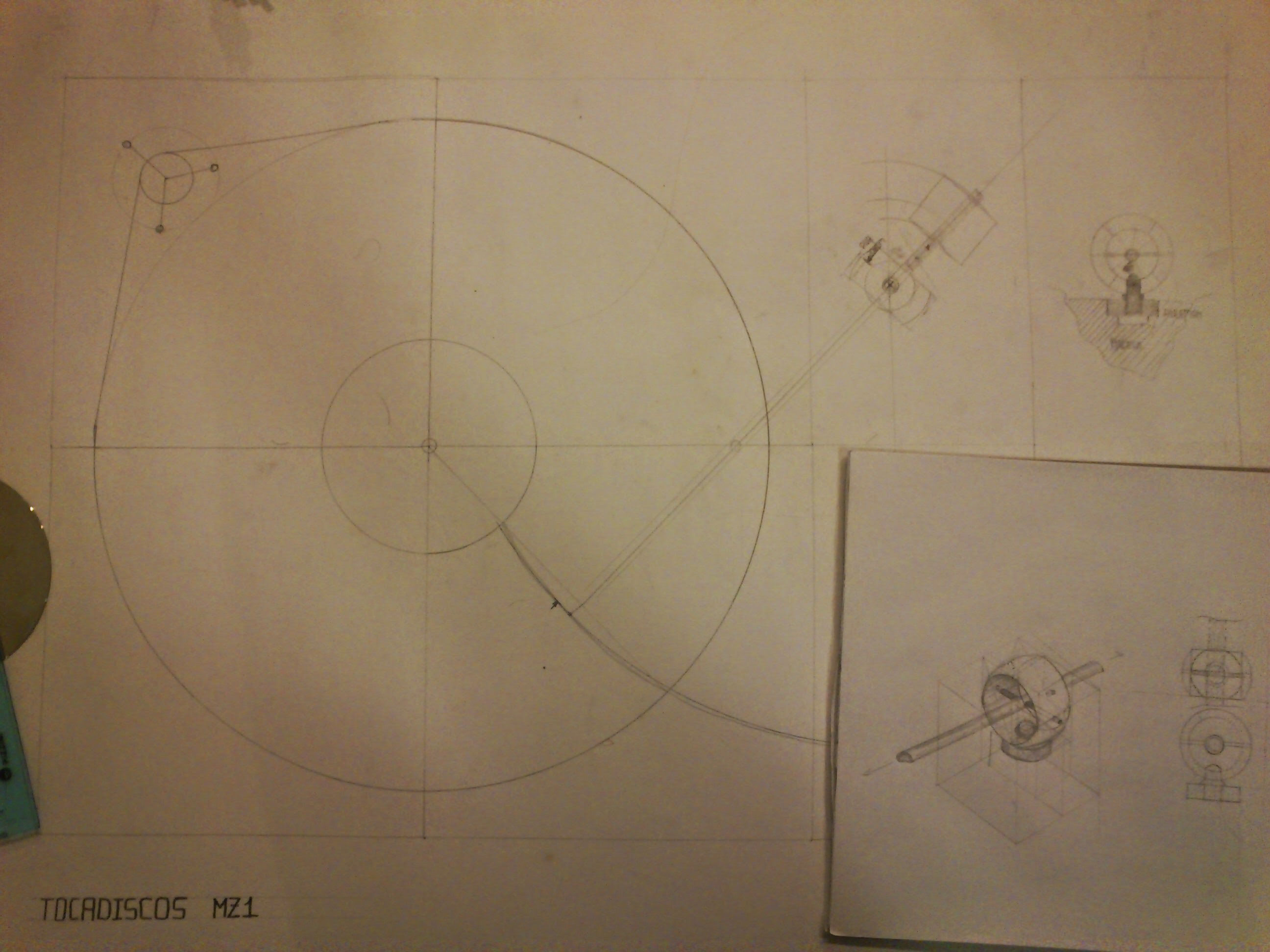

March 2013

First draft of the record player. At the moment, I called it MZ1, I never

used that name again.

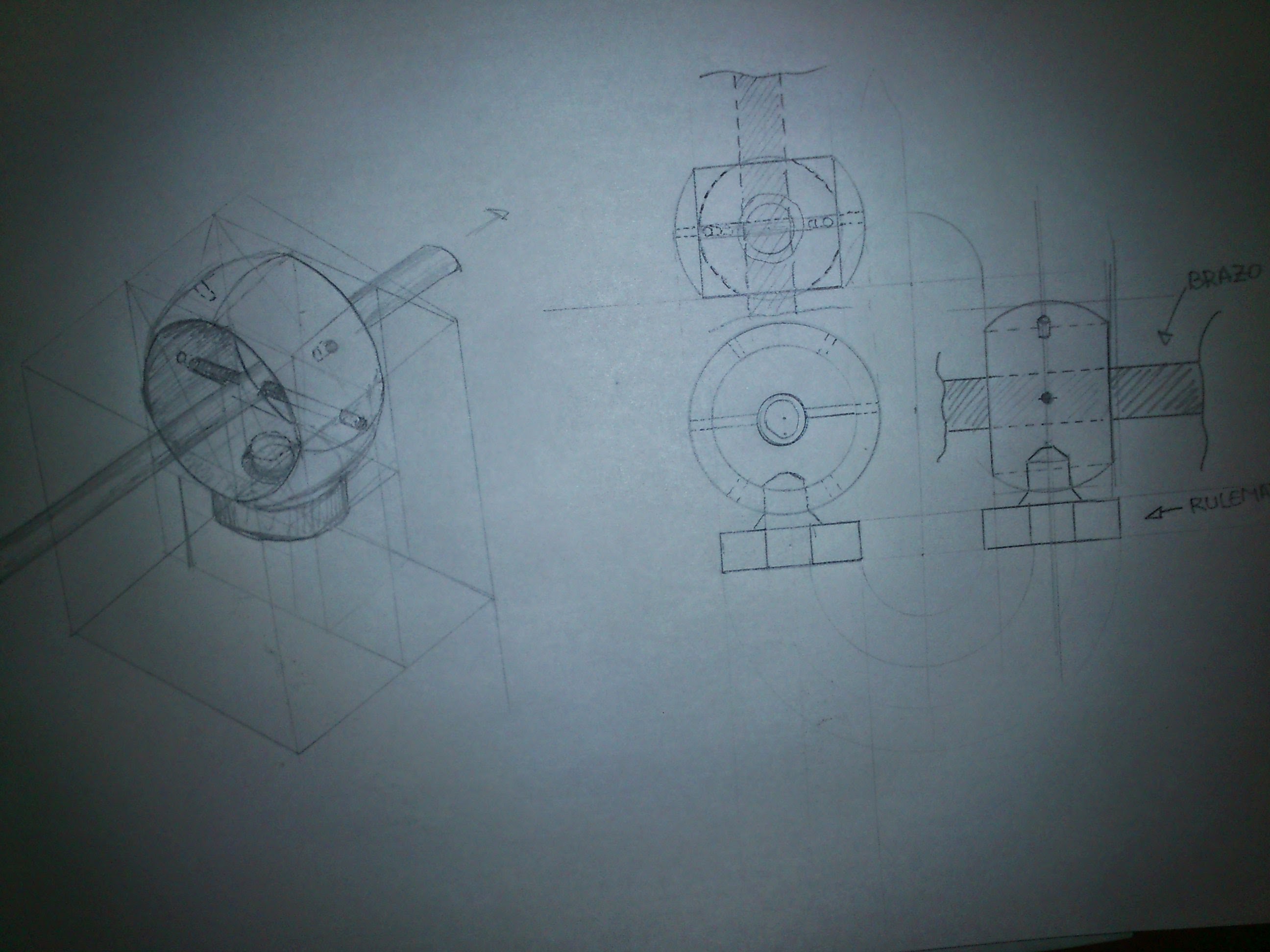

I also fantasized about some machined pieces for the arm base.

Building

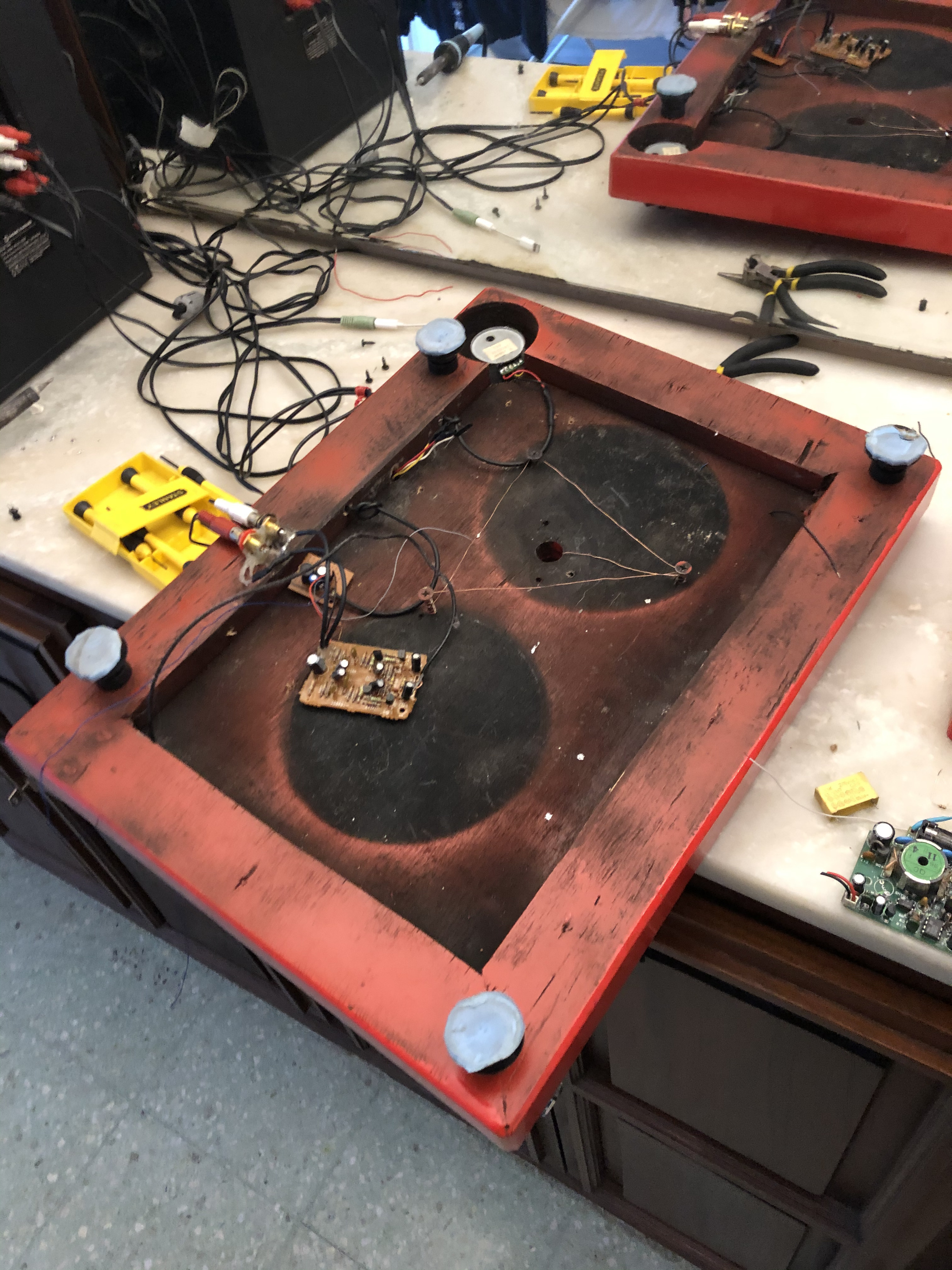

I wanted the turntable to be as heavy as a little motor can handle, so I decided to build it from wood and an old record player metal plate.

The two disks are joined using fiber glass and polyester resin.

I came up with a novel method to make it round

The body is also made from the same wood, the lower part is hollow to support future electronics. The hole in the corner is the space for the motor.

Here is how it looked all togheter, pay attention to the groove in the side of the main plate. That would be the place for the belt.

April 2013

Assembly

There is a missing record of the painting process, it was painted with orange car paint (Nitrocellulose lacquer). The motor we can see there is an old turntable motor, it has a short shaft so I used a random small pipe and epoxi to fix it in place. The belt is not such thing, it is a pizza rope (at least in Buenos Aires it was really common to receive pizza boxes with a rope around them avoiding accidental openings).

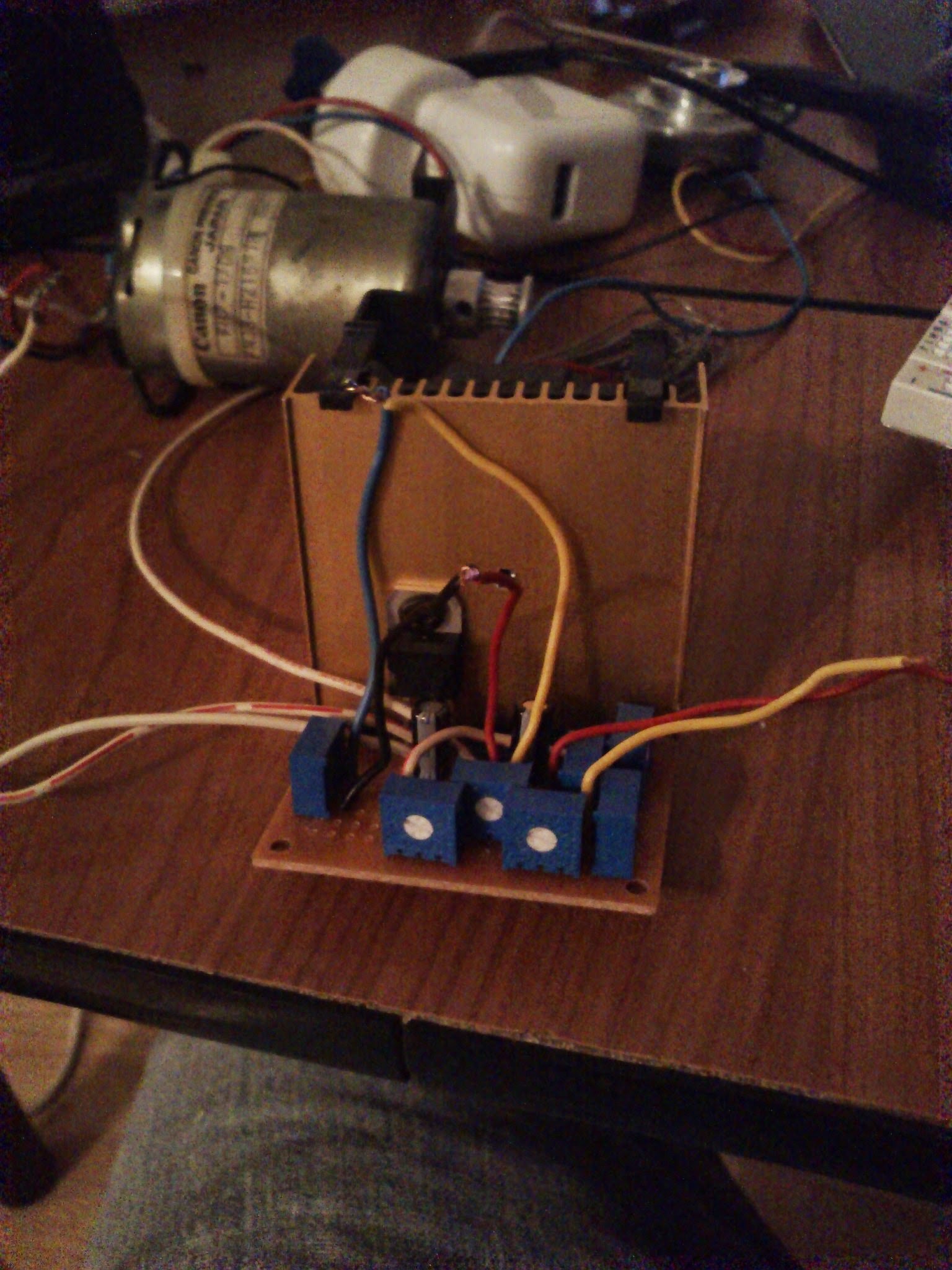

The first speed regulator, behind it you can see other motor options I was playing with. The original idea was to use a hard drive motor to drive the plate.

The hard drive motor ended up being a pain in the rear, those things are designed to run at high RPM. My approach was to use an amplified and soften PWM output from an arduino to fine adjust the speed of the motor.

On the upsite, the hard disk drive did work well, and the preamplifier at the time was not catching any interference (it was a pretty bad preamplifier).

On the downsite, it was a pretty bad preamplifier, so when I got a proper one it was catching a lot of PWM noise from both the line and EMI.

The first preamplifier was "borrowed" from an old sharp all-in-one stereo system.

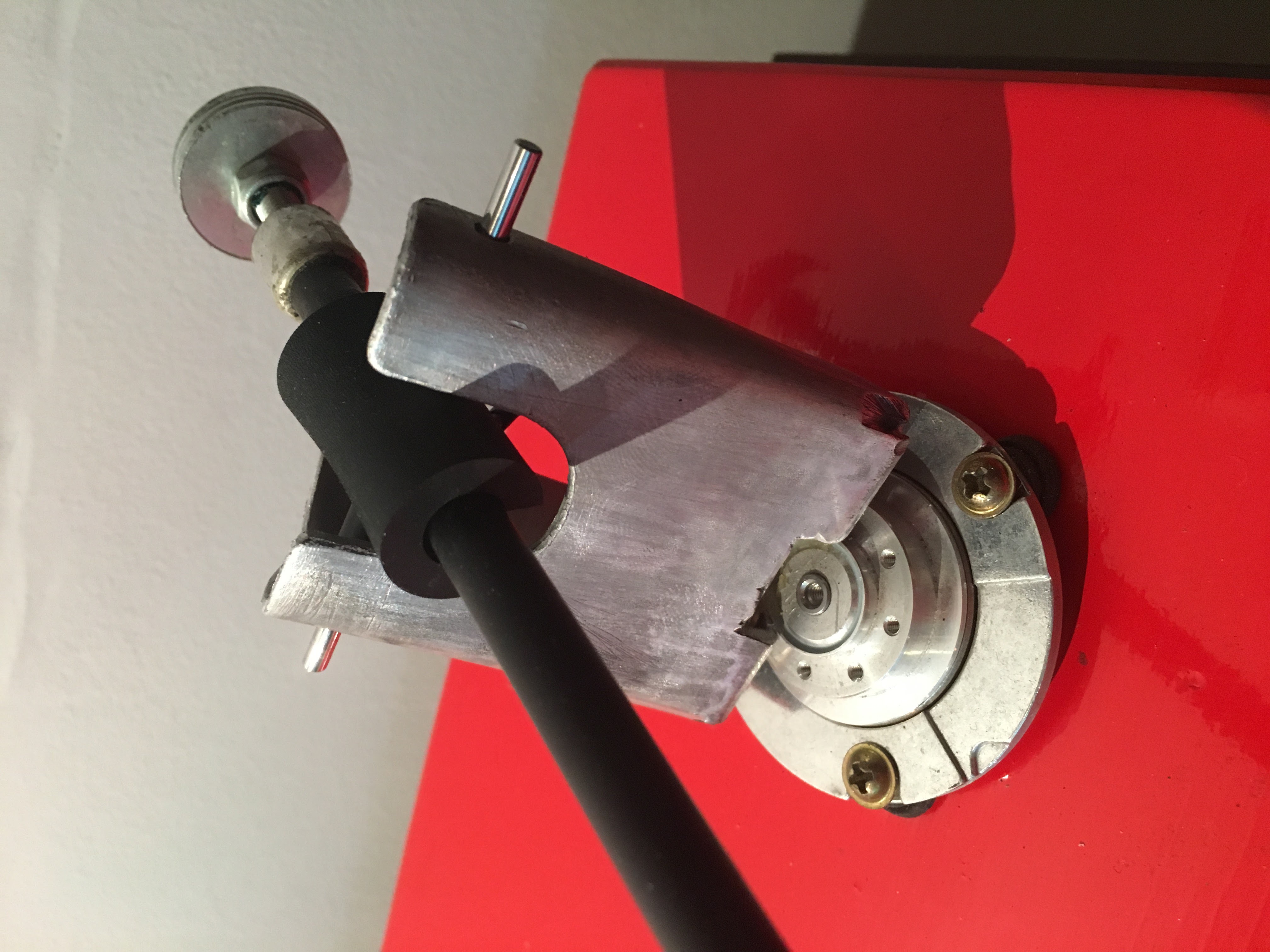

The arm base is built using a hard disk drive and a piece of aluminum from a heatsink.

The first version of the tonearm was a cheap curtain pipe, it was what I got at hand at the moment.

March 2016

Things happened, during a couple of years this project was collecting dust in a closet and I decided to continue it.

The speed regulation was still a problem, I wanted to test a more computalized solution for it. And the tonearm was a piece of a curtain.

I got the perfect candidate for the tonearm. A very conductive (to work as some kind of isolation, I hope) carbon-fiber fishing rod.

So far, this is how it looked and sounded

Speed regulation was a saga by itself. As explained before, several DC motors, brushless and stepper motors were tested. Every motor has its pros and cons.

| Kind of motor | Pros | Cons |

|---|---|---|

| Brushless (HDD) + Arduino |

|

|

| Brushless (HDD) + SineWave (MP3 + Amplifier) |

|

|

| High power DC motor |

|

|

| Low power DC motor (walkman motor) |

|

|

| Another turntable DC motor |

|

|

Here is a lost video of one of the speed regulation tests:

As you can hear, it is far from ideal but better than the first one.

An interesting experiment was to add a IR sensors to the plate and write a small C program to regulate the speed accordingly. Sadly, it did not work as expected, the speed continuously falls into local minimums. And it was annoying to hear.

I even tried with a compiled Long Short Term Memory (LSTM) neural network but without success, obviously, it was an overkill "Neural-network-powered home-made turntable".

Mid 2019

I got a proper belt and removed the pizza rope. Farewell pizza rope, thanks for six years of music.

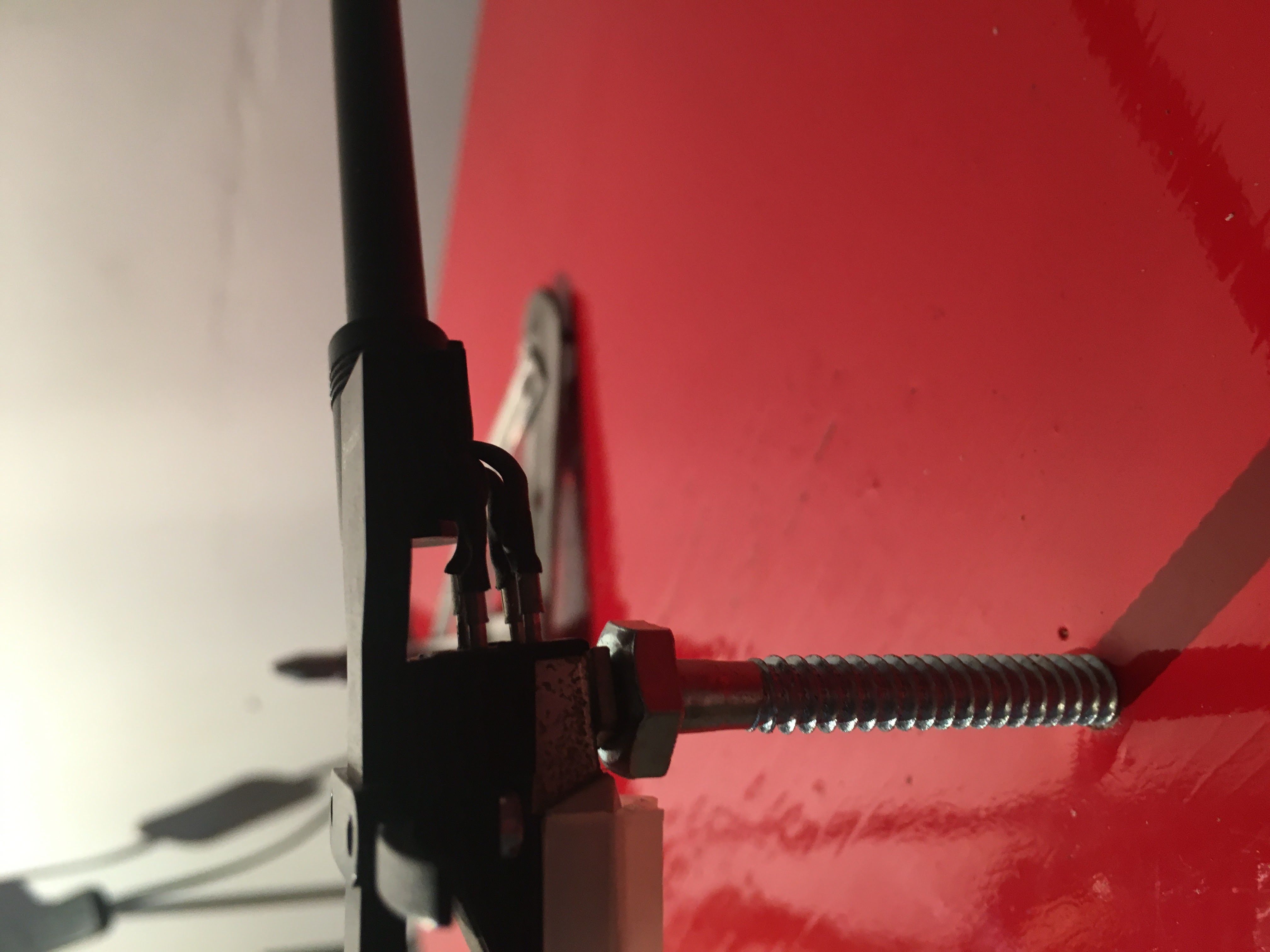

In the same upgrading rage, female RCA headers were added to the main frame. Before it was a soldered short cable with male RCA headers in one end.

January 2020

There was a Hum. It ended up being two hums, a line hum due to the transformer, and an interference hum due to the motor.

I solved the issue by adding a choke and low-pass filter both to the preamp and the motor.

A couple of condensers were required for the motor too, surprisingly a 10µF in parallel to the motor solved most of the motor hum.

The heavy part was on the preamp side. To start, I isolated the preamp in a FitBit box covered with aluminum tape as seen in the pictures.

Then I had to create a low-pass filter for something like 30Hz to not let the motor hum pass. I did that using a custom made filter (I tested in the protoboard until it sounded good-ish).

It consists of a 100Ohm resistor feeding a ferrite core coil, which feeds a 220µF condenser. Both ends of the circuit have a 475nF ceramic condenser to ground.

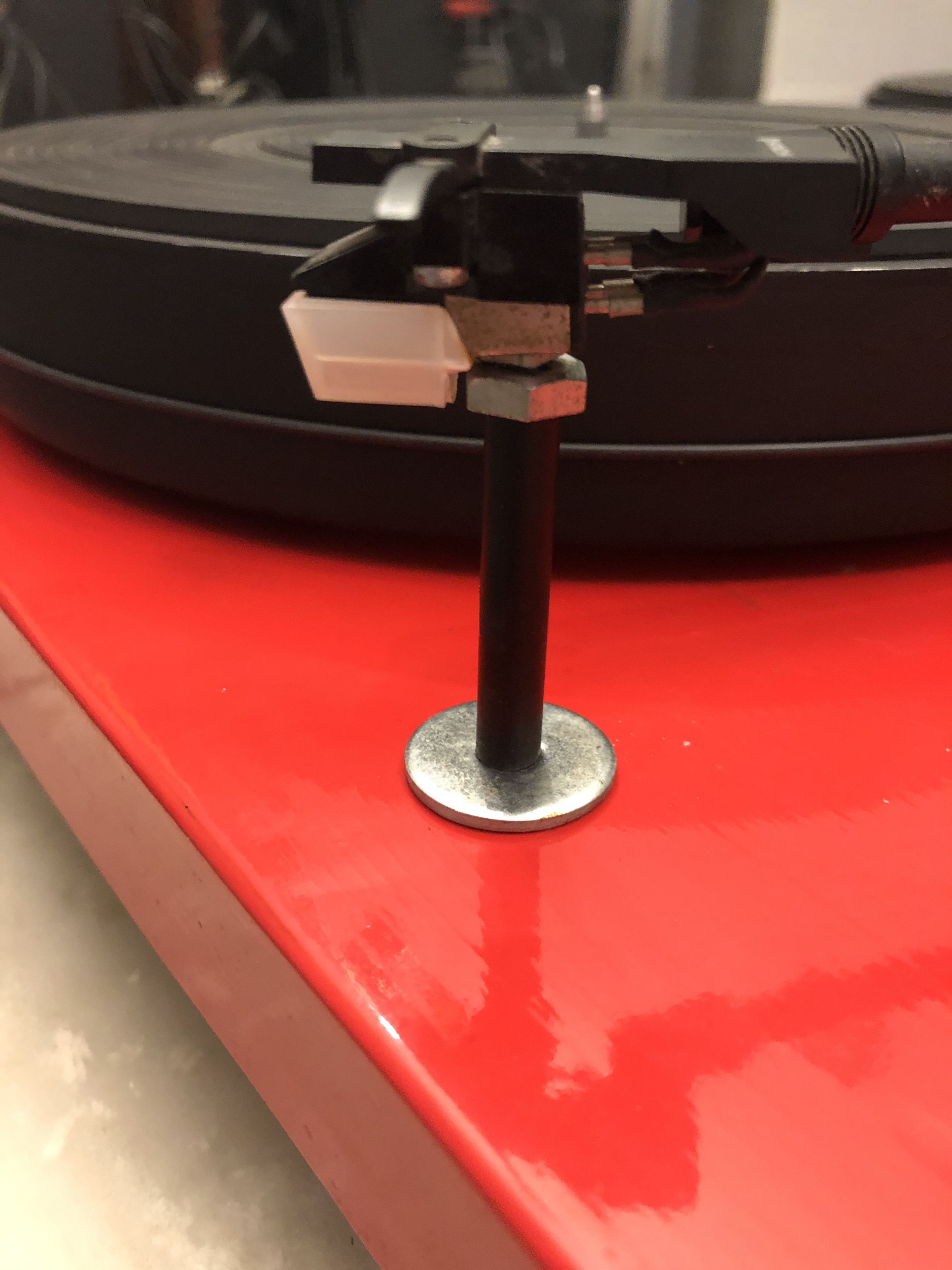

Lastly, I added a cover for the bolt+magnet holding the tonearm, it looks prettier now.